Context:

Sime Industrial operates in multiple countries, including Australia, New Zealand, Papua New Guinea, China, Singapore, and Malaysia. Within each region, toolstores provide technicians with the tools and assets needed to complete service work. These tools are expensive, consumable, and easily lost if not properly managed. They also require regular inspection and calibration, which is often overlooked until tool-related issues arise, resulting in millions of dollars in losses each year.

Understand the problem:

We’re currently using a system called SAM, which was developed about 15 years ago. Many of its features are now outdated and no longer meet today’s operational needs.

During the morning and afternoon peak times, when staff are clocking in and out, all technicians come to borrow or return tools at once. This leads to long queues and very low efficiency. To speed things up, toolstore staff often skip checking the condition of the tools, and they don’t verify whether any damage has occurred before accepting returns. Over time, these issues just keep piling up, and the situation continues to deteriorate.

At the same time, management wants tool usage to be linked to the jobs being serviced, so that the associated costs can be accurately charged to customer invoices. However, this hasn’t been implemented at all, resulting in significant financial losses for the company.

Define the problem.

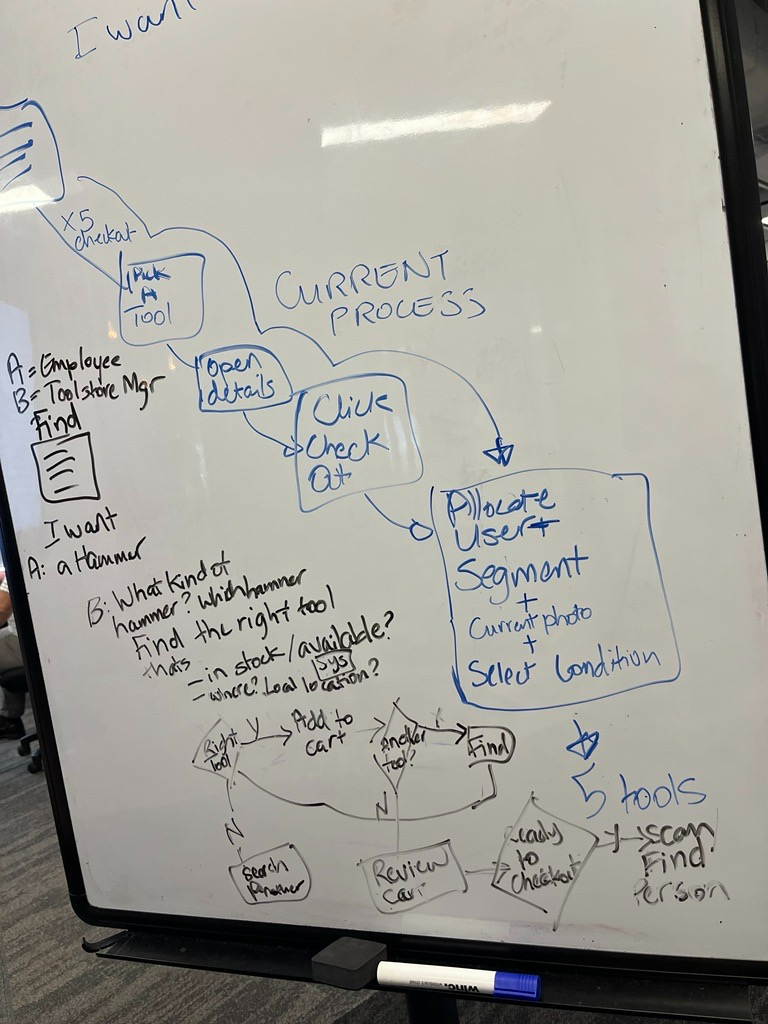

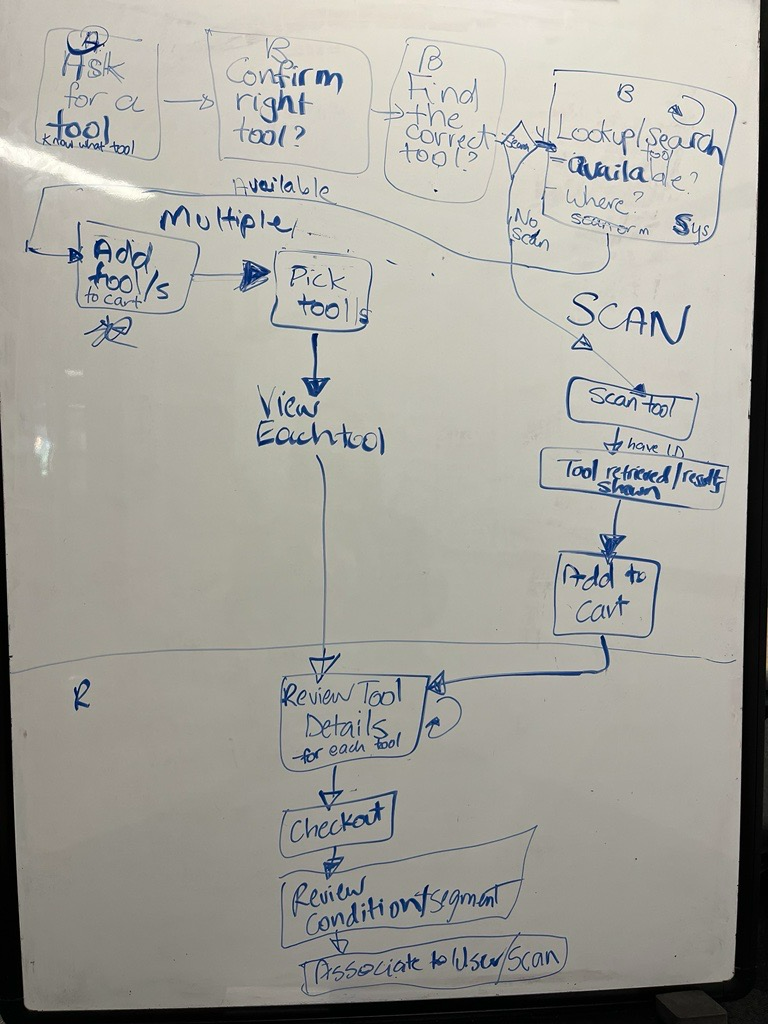

As a team, we defined the problems and user needs identified in the previous session. These include the peak-hour congestion when technicians return or borrow tools, the requirement to link consumable asset usage to customer invoices, and the need for a proper process to check tool conditions when they are returned. We also considered the challenge of maintaining high efficiency when large tools are stored far from the toolstore, additional requirements such as enabling technicians to use self-service toolstores, and contingency scenarios like scanner failures during peak periods.

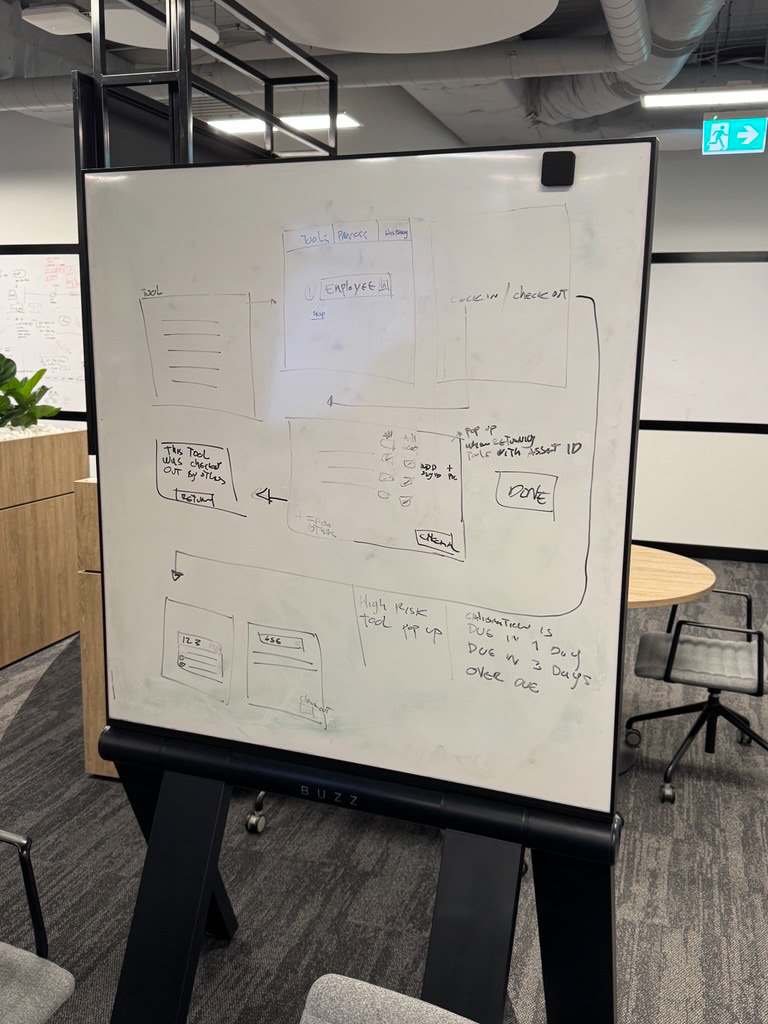

Ideation

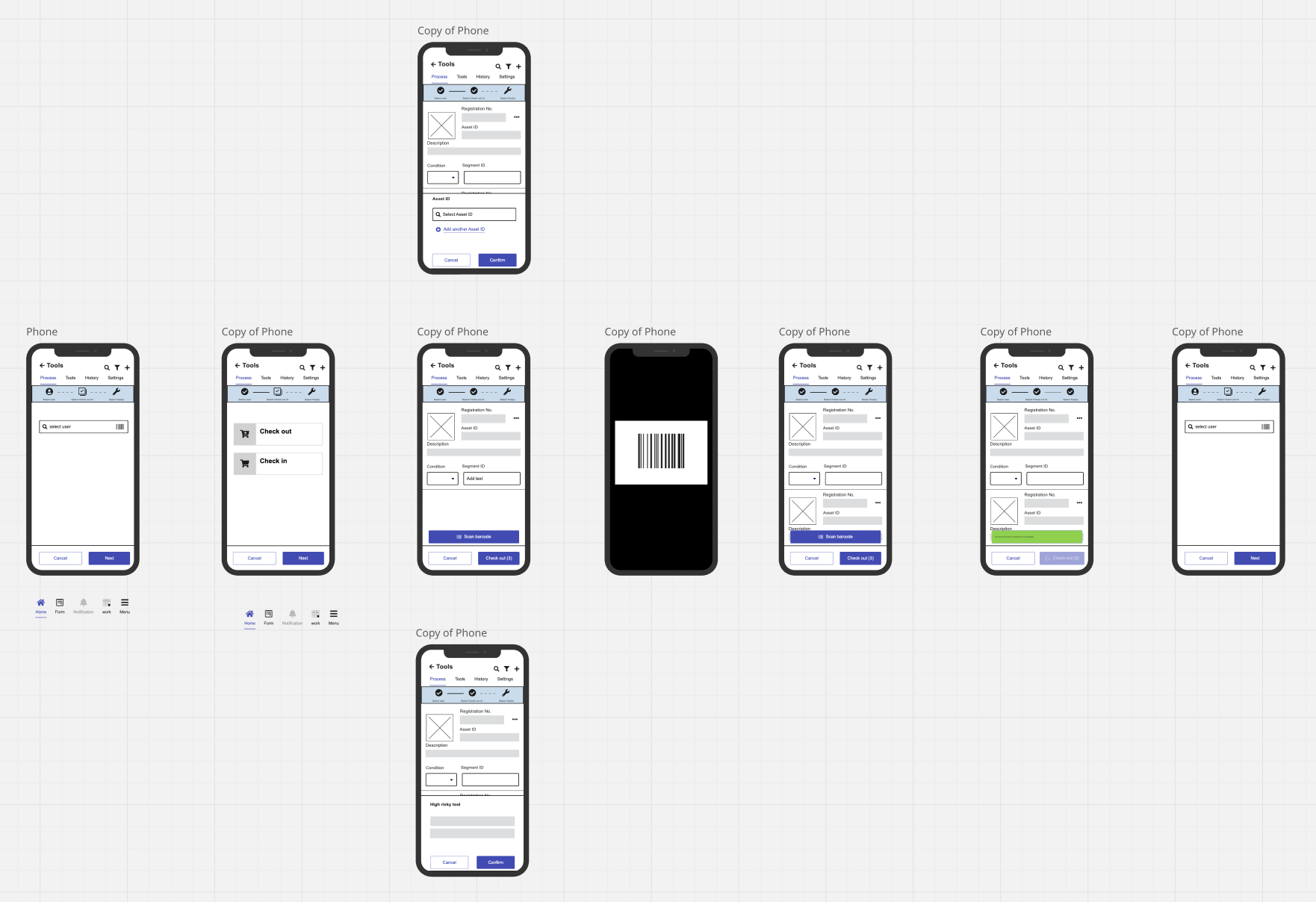

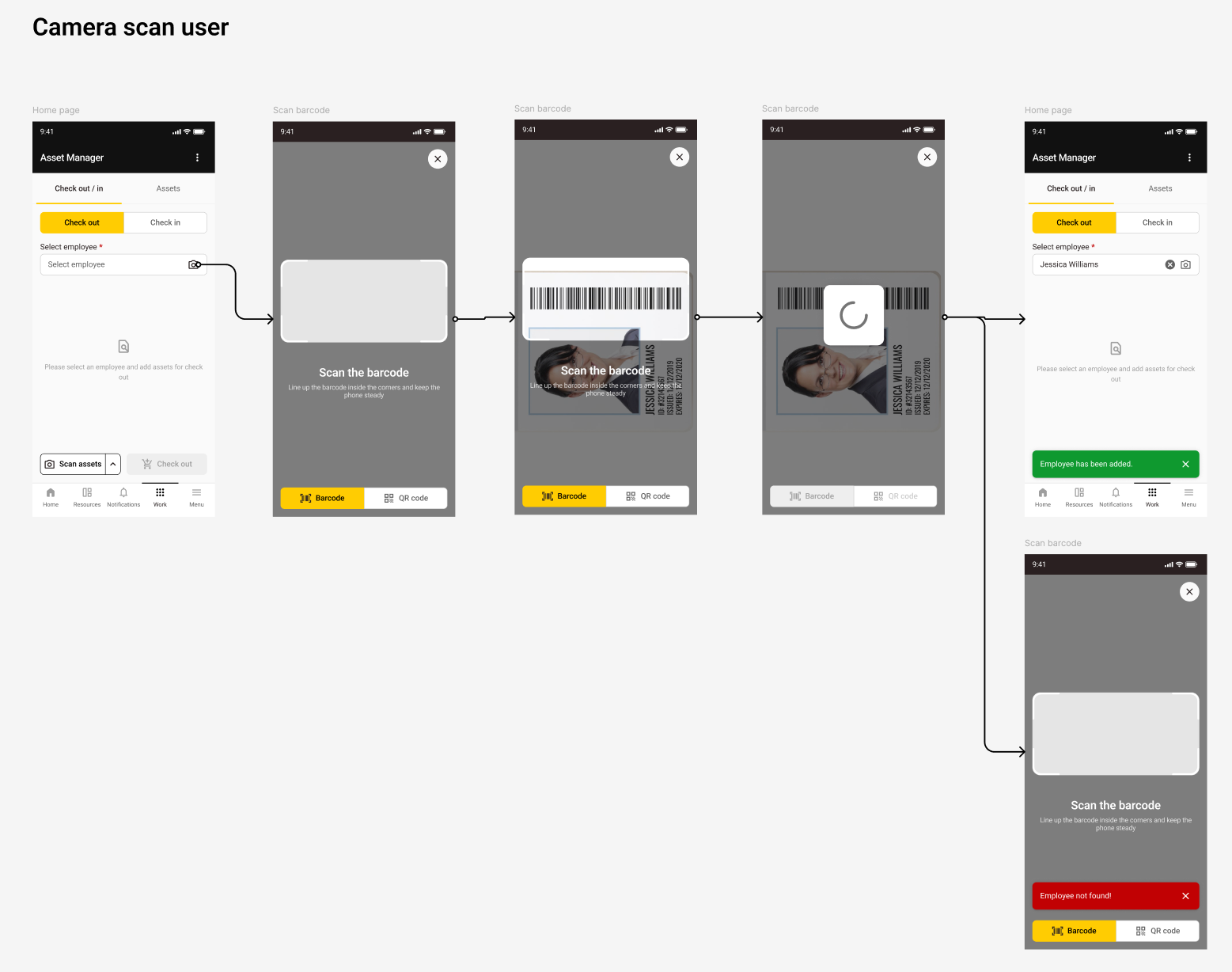

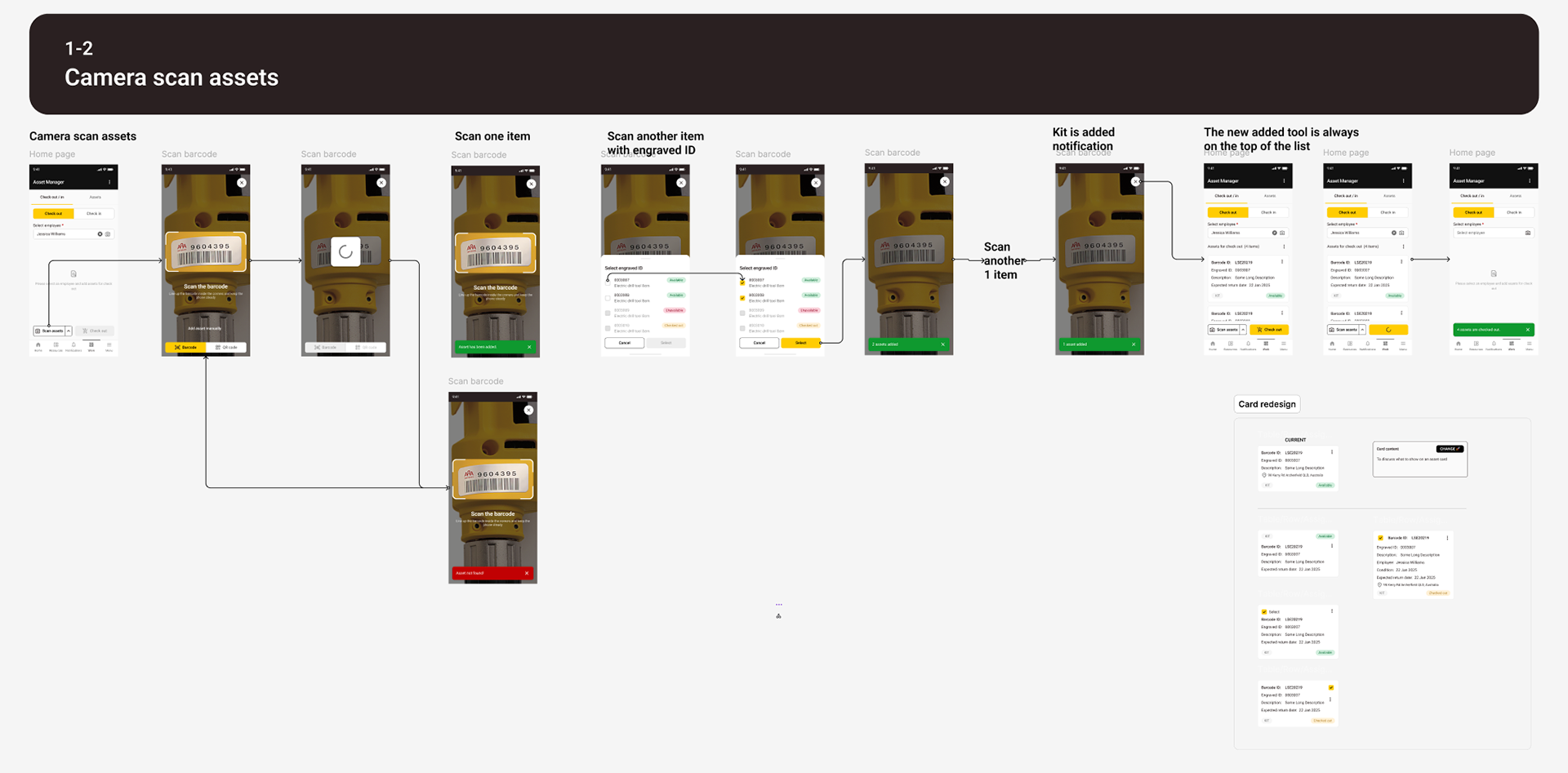

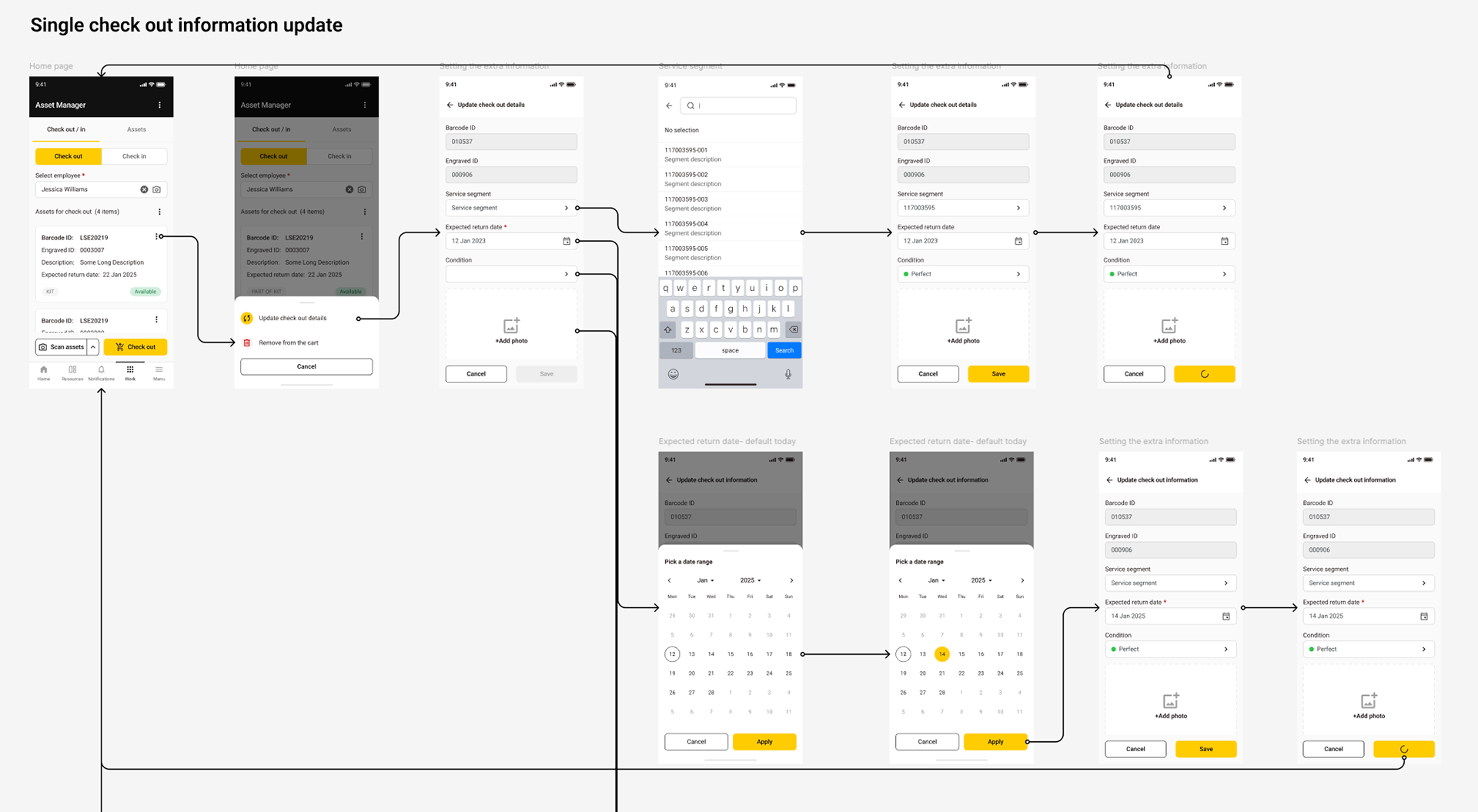

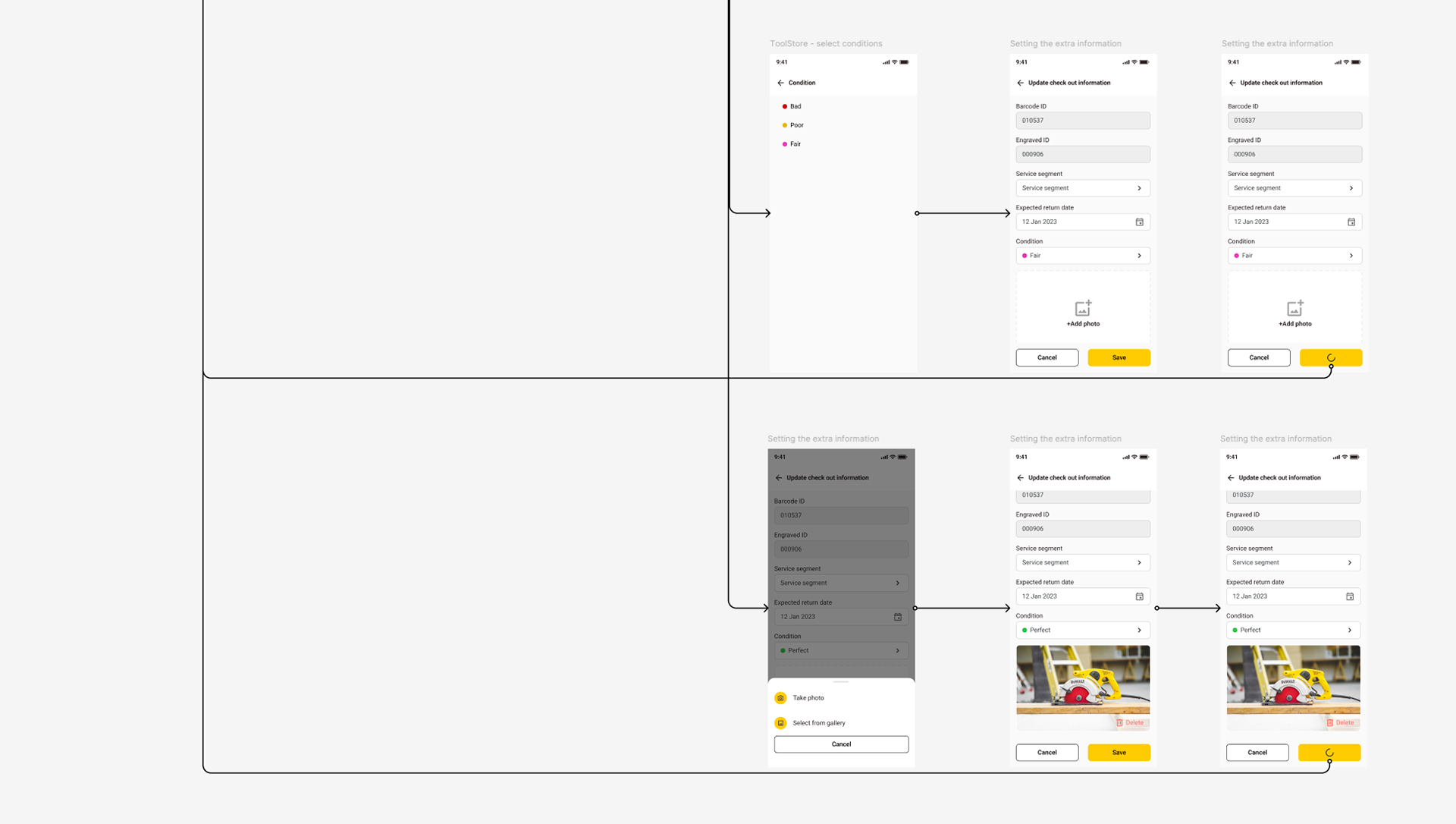

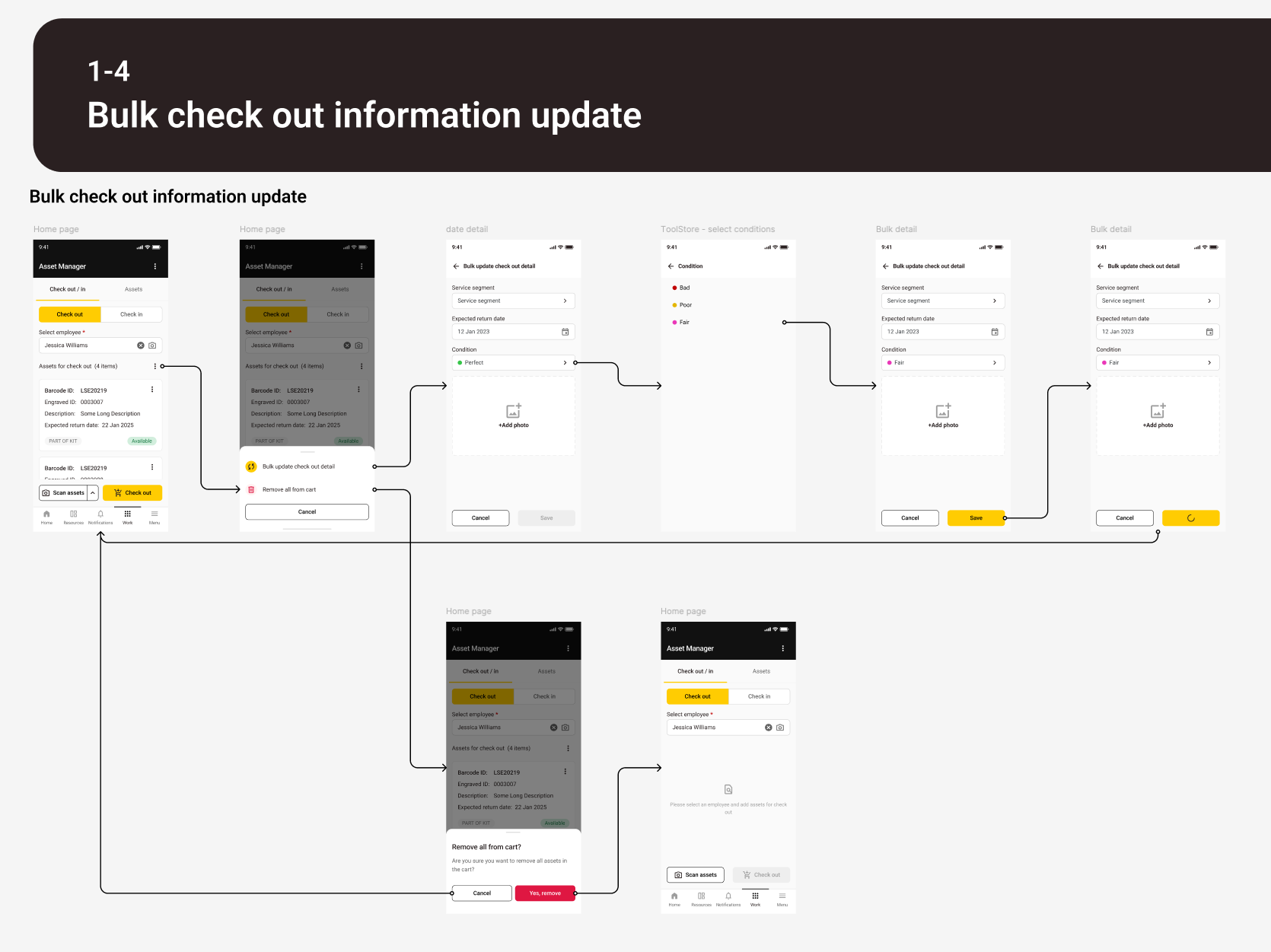

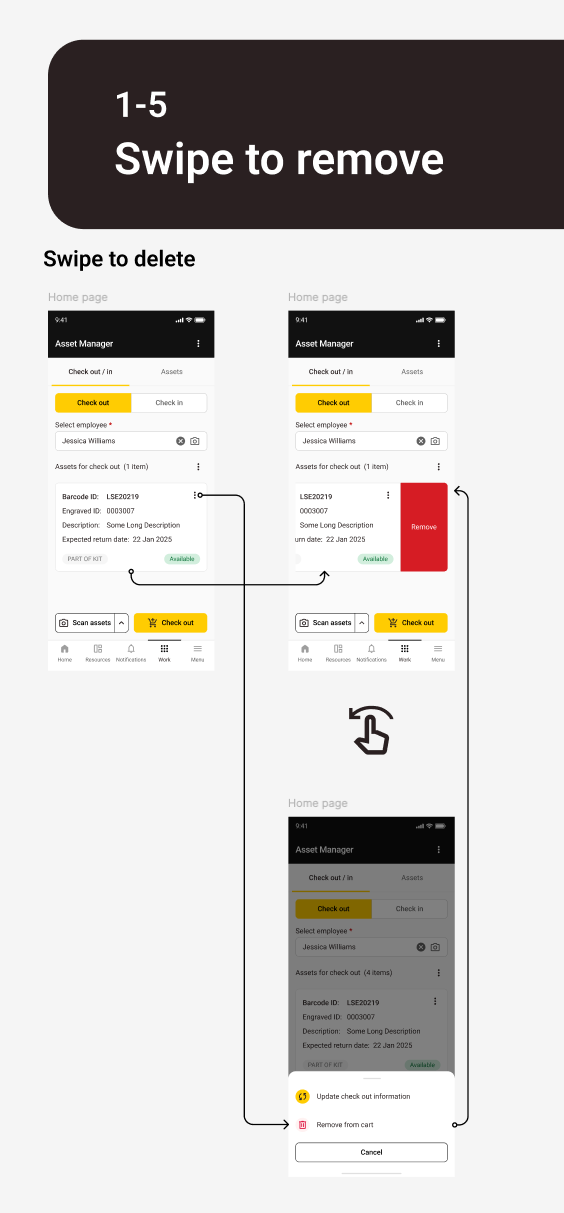

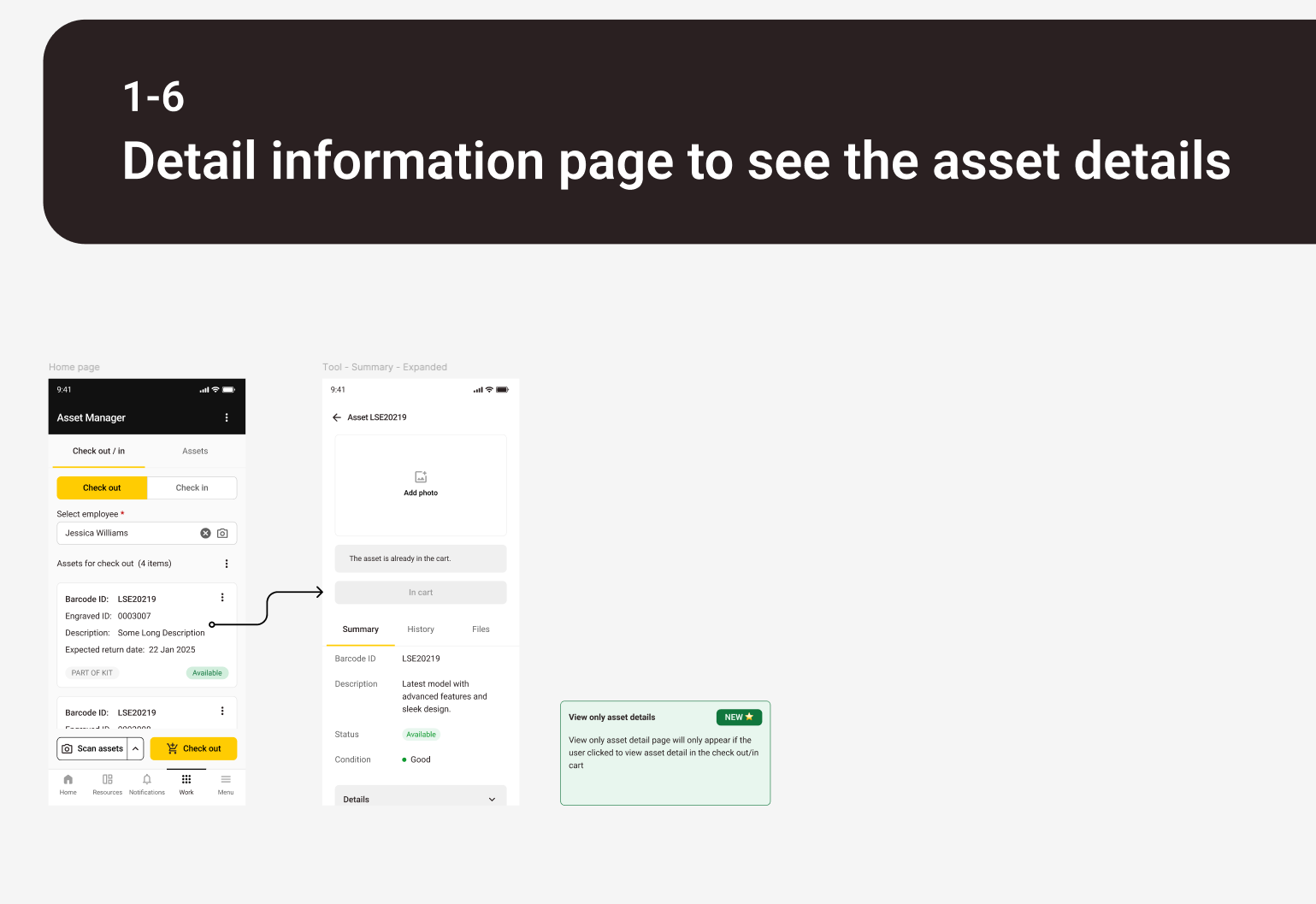

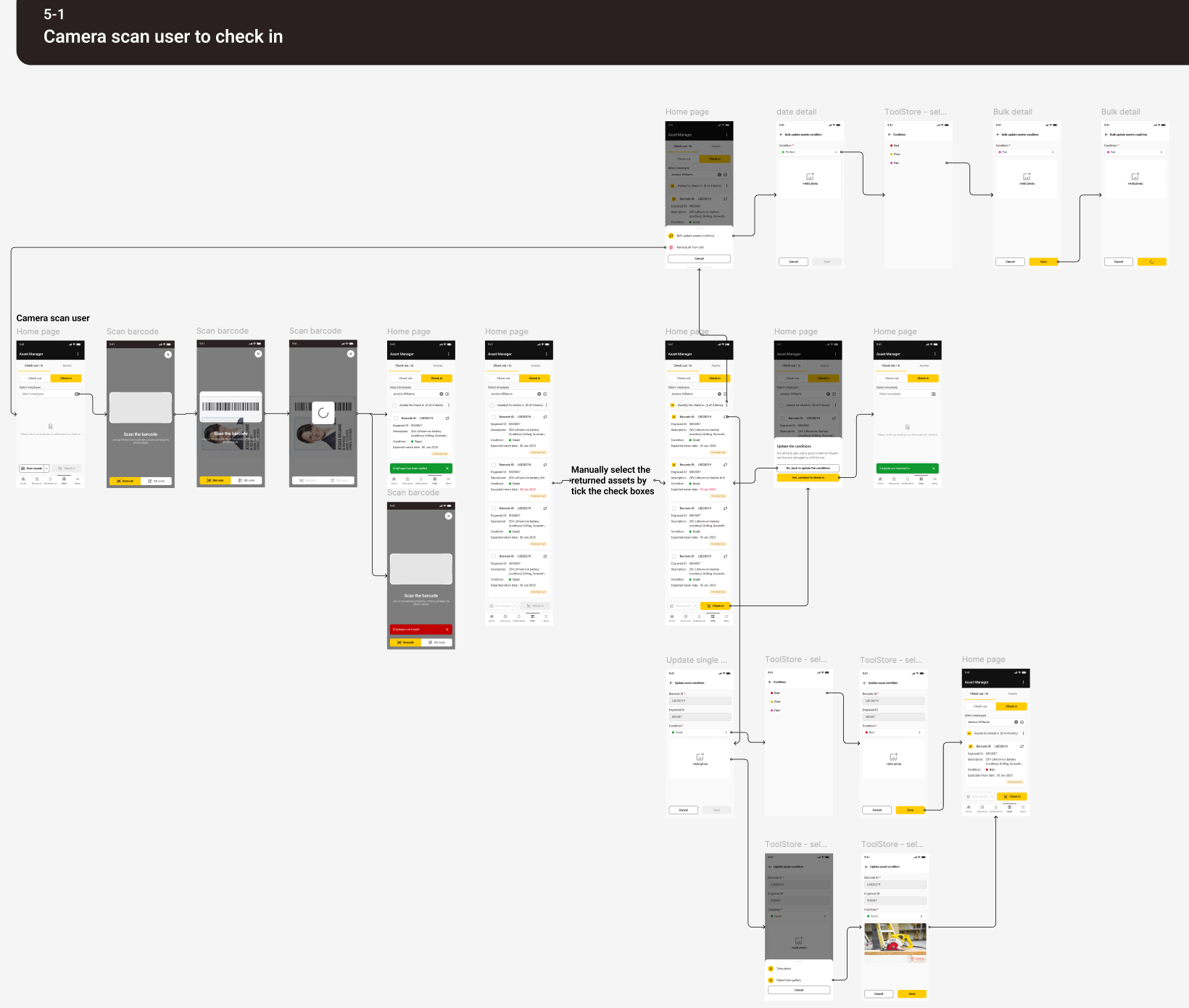

Prototyping

Test

We tested the design in the Brisbane toolstore with technicians, toolstore staff, managers, and the company’s asset managers. They confirmed the improvements and also raised questions and concerns from their own perspectives, including several scenarios that still need to be addressed.

Iteration:

Based on the feedback, our design focused on replacing the old system, which had been in use for nearly 15 years, and addressed key issues such as tracking who currently holds assets and linking consumable assets to projects or customer invoices. While these improvements were valuable, simply retiring the old system and fixing a few problems did not fully meet users’ expectations. Both toolstore managers and business stakeholders are looking to address additional challenges, including improving efficiency, inspections, and calibrations, which are highly important to them. Furthermore, after-hours scenarios remain a significant headache.

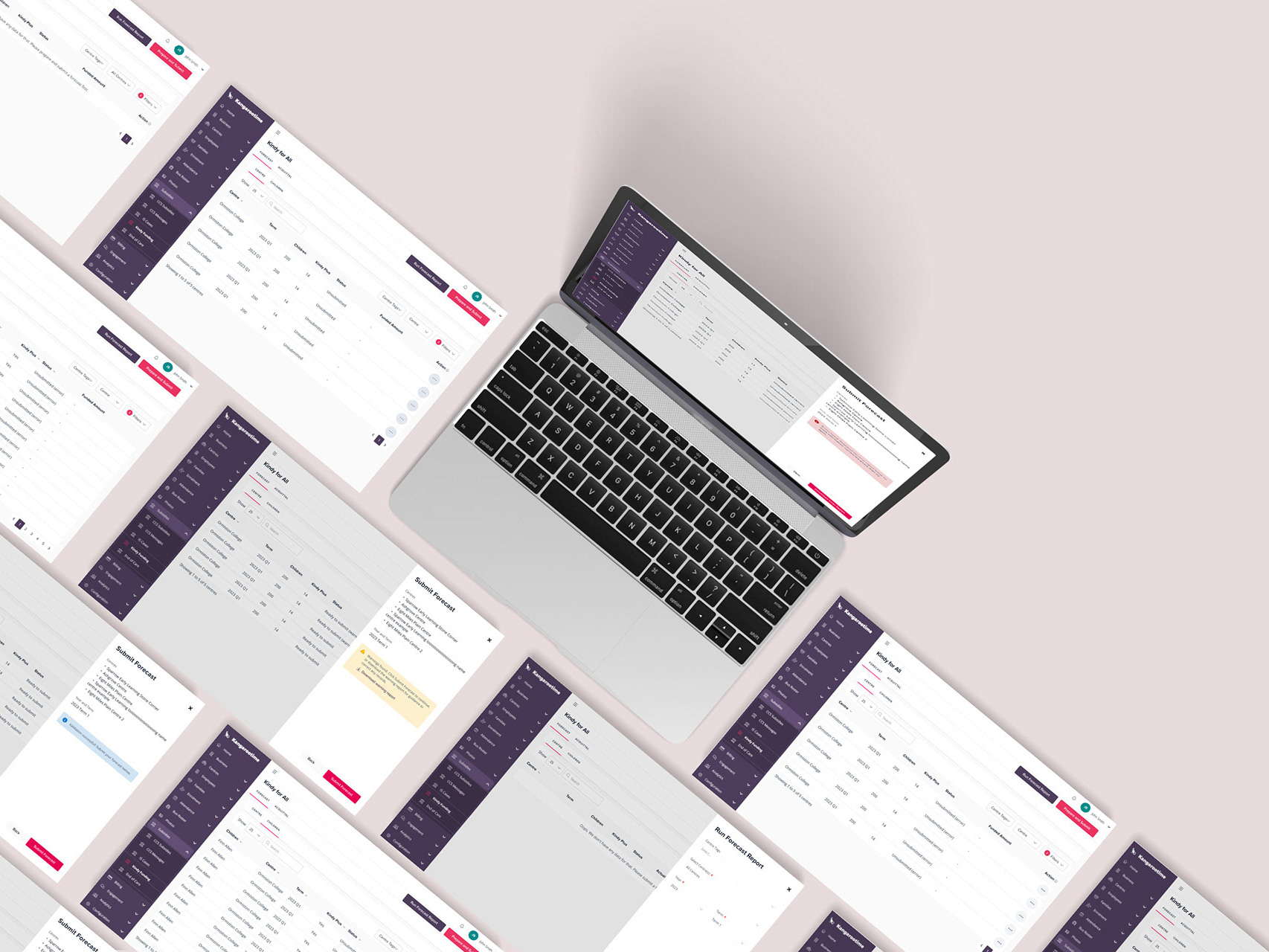

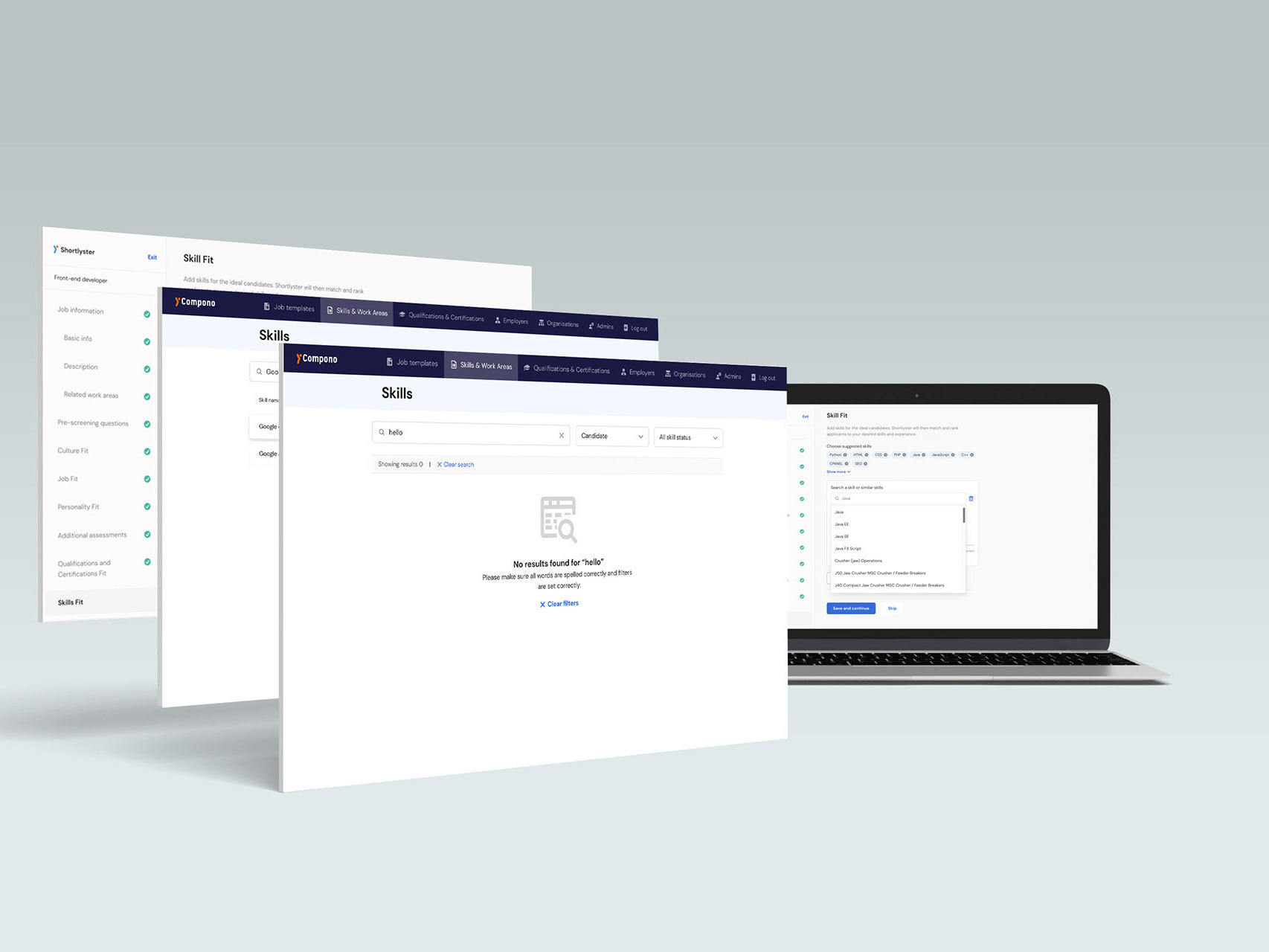

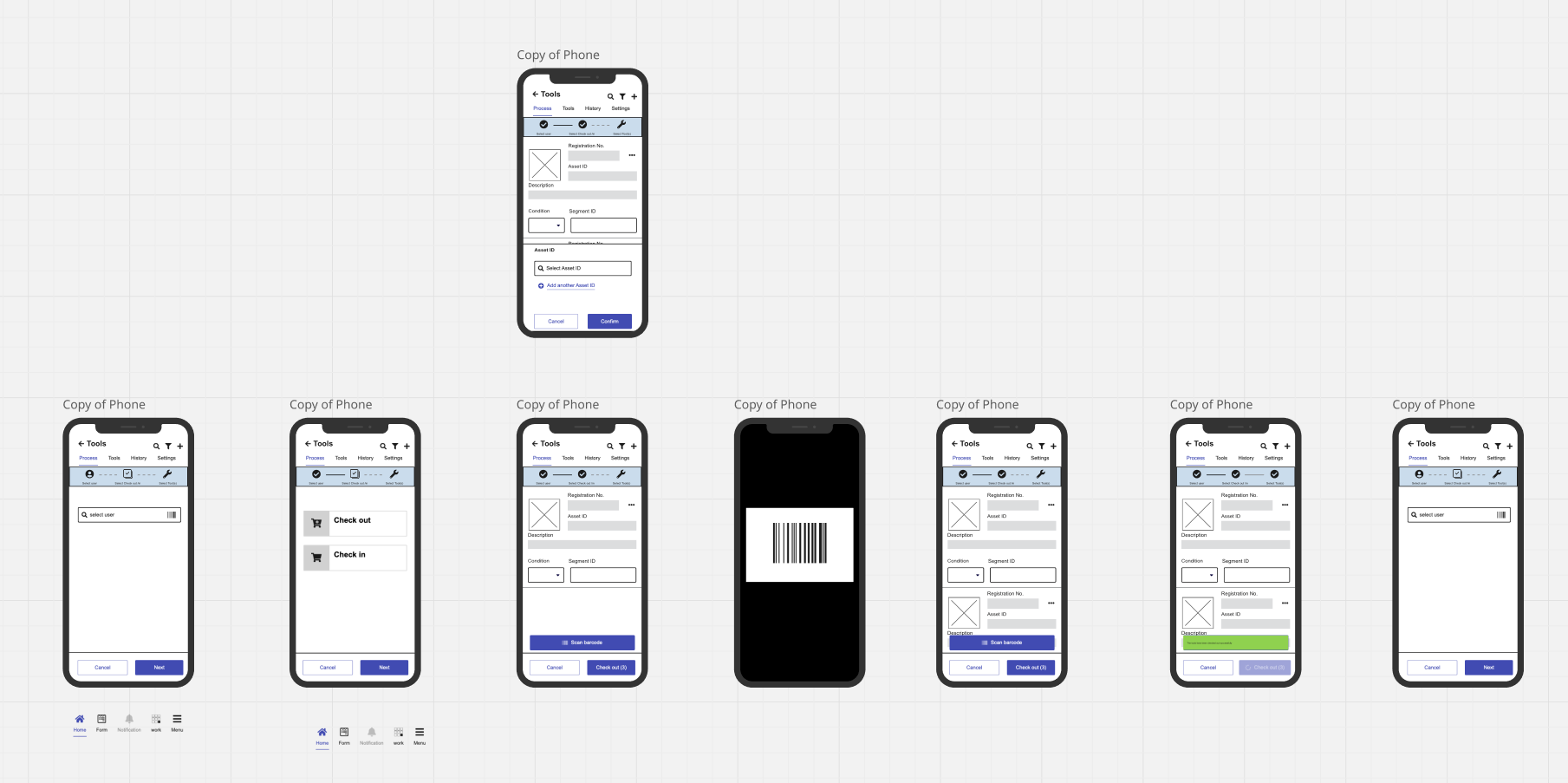

Hi-Fi prototyping

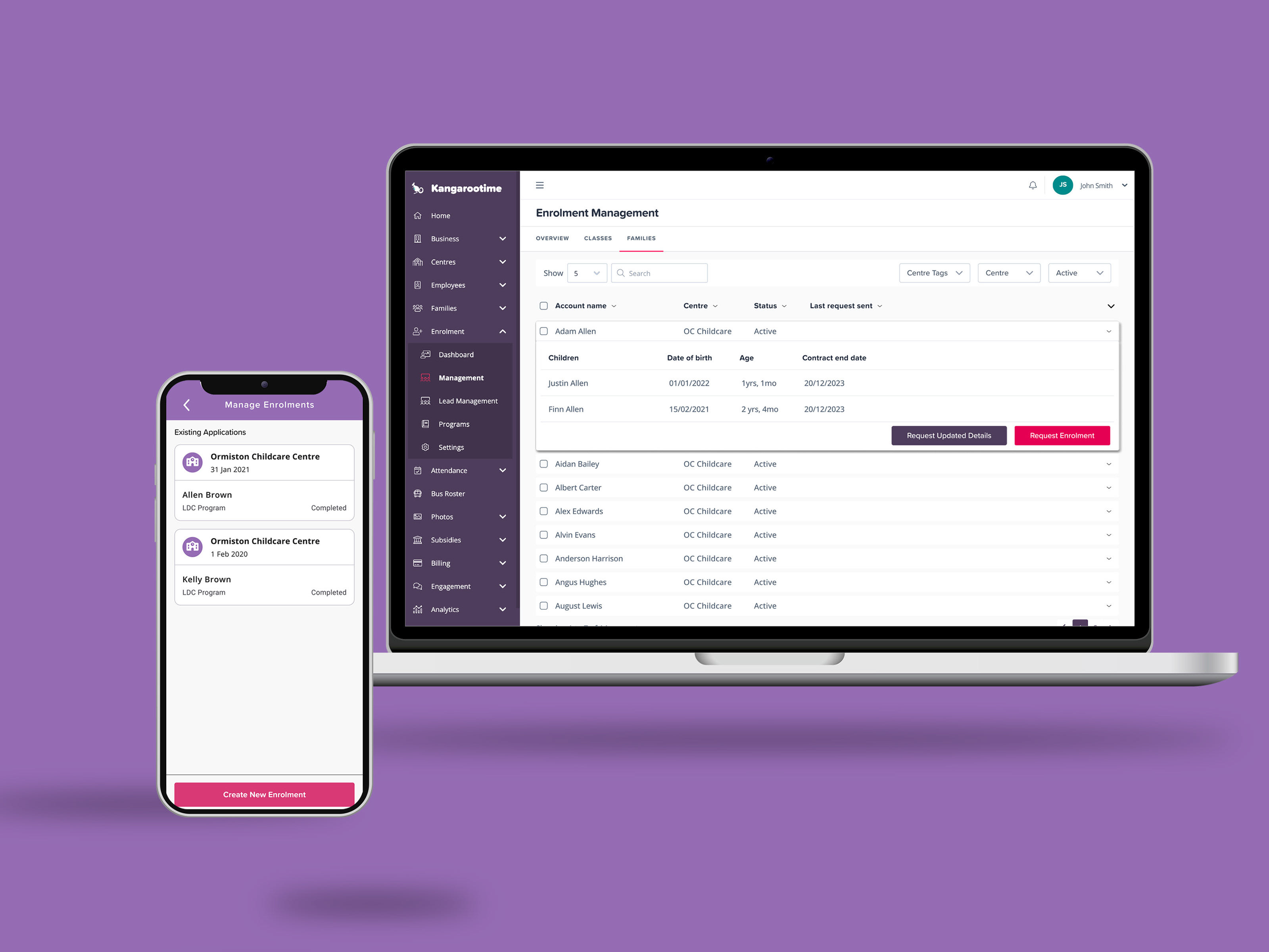

Pilot and Outcome

All designs were tested onsite with relevant stakeholders, including toolstore staff, technicians, toolstore managers, and asset managers, and the feedback was overwhelmingly positive. The ease of use, which requires minimal training, will support the broad implementation of the new design system across ANZ and South Pacific Asia tenants. The expected outcomes include replacing the old system, saving tens of thousands of dollars per year, and, through the new system, reducing millions in asset-related costs while passing these costs accurately to customers via invoices.